Passionate – Dedicated – Professional

The steps we follow to

achieve your goals

Passionate Craftsmanship, Flawless Results. From kitchen islands to reception desks, every custom project is vital. Our meticulous process guarantees exceptional outcomes. Our dedicated team manages every step, ensuring flawless surfaces delivered swiftly.

Passionate – Dedicated – Professional

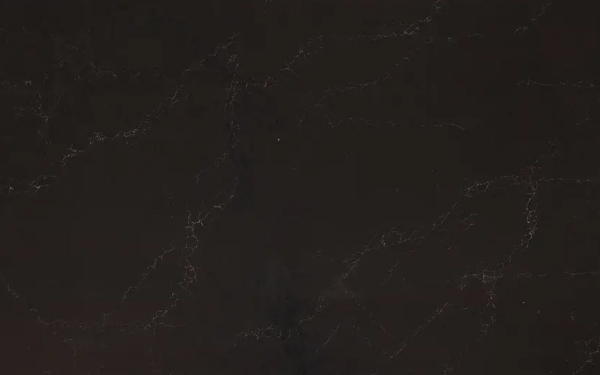

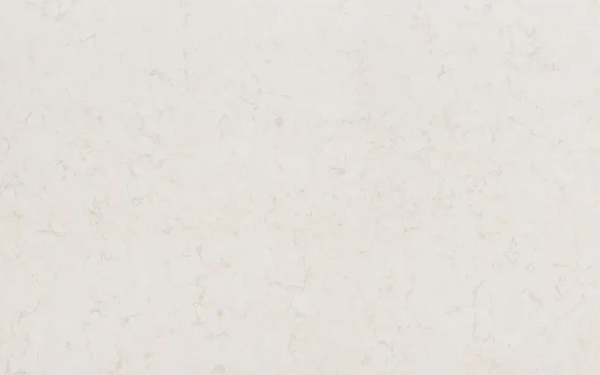

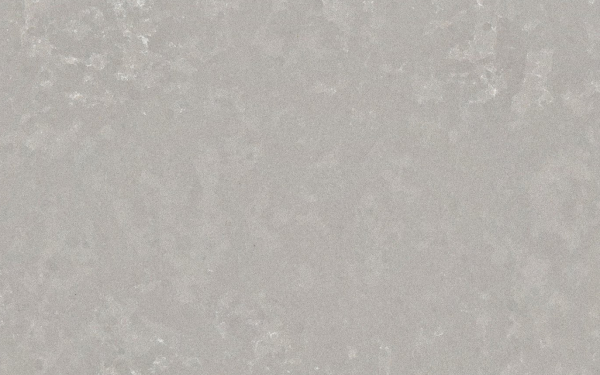

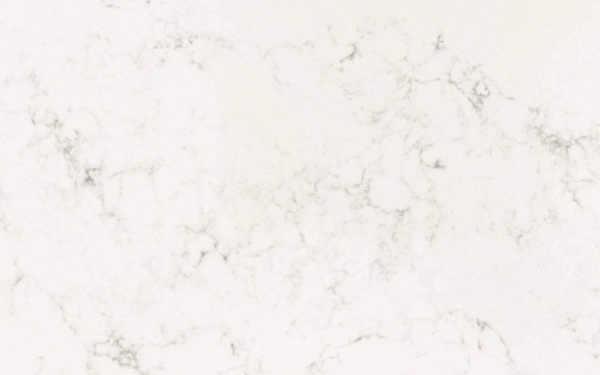

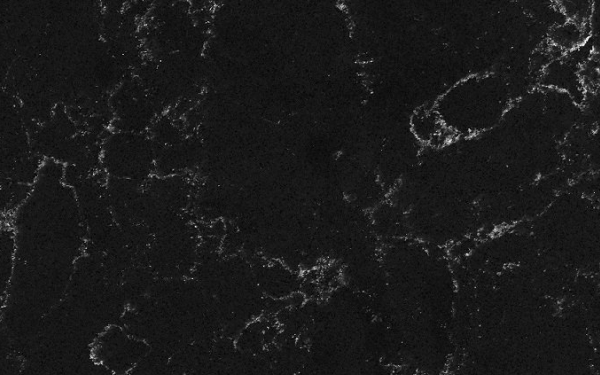

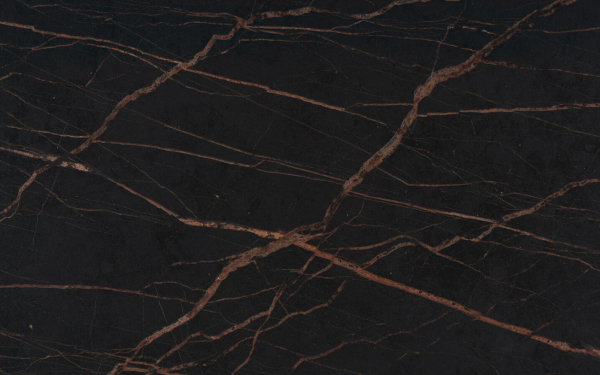

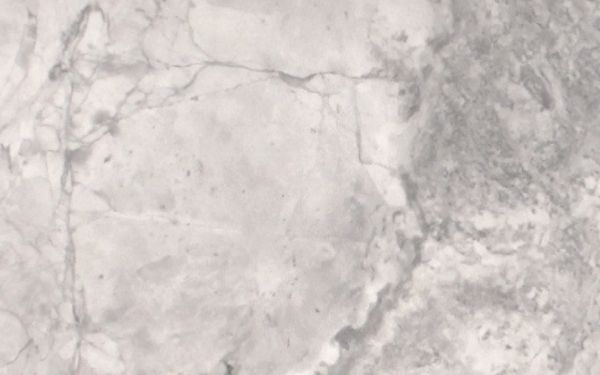

Our products

Explore our stone collection: timeless elegance, enduring quality. Discover a range of premium stones, meticulously sourced and crafted to elevate your spaces with natural beauty and lasting sophistication

Frequently Asked Questions

Curious about our process or installation preparations? Explore a compilation of frequently asked questions by our customers.

Cleaning a quartzite countertop is similar to caring for a granite one. Use a soft cloth or a paper towel to wipe up counters regularly with a gentle cleanser and water. Remember to avoid using dish detergent since it leaves a greasy film, which can dull or leave streaks on stone surfaces. Keep all bottles and containers on a dish, including dish detergent, to prevent residues touching the surface of the countertop. Constantly dry the underneath off anything placed on the countertop, and wipe off water around the faucet and fixtures; water will calcify and though it is cleanable using a neutral cleaner once a week, it is also preventable.

Wipe up your granite countertop after each use with a neutral cleaner, read the label to identify a cleaner safe for stone surfaces. Avoid using dish detergent since it leaves a greasy film, which can dull or leave streaks on stone surfaces. Keep all bottles and containers on a dish, including dish detergent, to prevent residues touching the surface of the countertop. Constantly dry the underneath off anything placed on the countertop, and wipe off water around the faucet and fixtures; water will calcify and though it is cleanable using a neutral cleaner once a week, it is also preventable.

As with any surface, simple preventative measures can be taken to protect countertops. Always wipe up spills and moisture as quickly as possible; prevent etching and stains by religiously using cutting boards, trivets, and coasters. Acidic products are common in the kitchen, specifically when caring for marble surfaces, wipe off immediately substances including tomatoes, citrus fruits, juices, alcohol, vinegar, red wine and oil. Keep all bottles and containers on a dish, including dish detergent, to prevent residues touching the surface of the countertop. Constantly dry the underneath off anything placed on the countertop, and wipe off water around the faucet and fixtures; water will calcify and though it is cleanable using a neutral cleaner once a week, it is also preventable.

Quartzite on one hand, contains minerals and nothing else. Quartz, the mineral, is the main ingredient. A quartzite stone is 100% natural and comes directly from the earth, made from geologic processes, over millions of years. Some types of quartzite contain smaller amounts of other minerals that give the stone color and character. The most well-known quartzite quarries are located in Brazil, though there are quarries along the planet including in Canada, India, Italy, Norway, and Sweden. Conditions such as the depth at which quartz is formed and the time it spends under the earth defines how porous a quartzite is, resulting in the conditions it can endure. On the other hand, even though the name “quartz” refers to a natural mineral, engineered quartz (sometimes referred to as “engineered stone”) is a manmade stone. It’s the product of bonding quartz particles together with resin, pigments, and other ingredients; in a mold. Manufactured quartz is made in factories in the United States, Europe, and Asia, among other locations. The mix in the mold is put under vacuum conditions, vibration, and pressure; this process is called “compaction by vibrocompression vacuum process.” The slabs are compressed at around 30 pounds per square inch, and heated up to 360° (around 180° C)F for around 40 minutes. The heat and pressure used to manufacture a slab are by far minor than the conditions that happen in nature. Due to the use of resin, engineered quartz results in having low porosity, nonetheless, this makes engineered quartz softer than natural quartzite. For application purposes, quartzite can be used indoors and outdoors indistinctly. From countertops and flooring, to outdoor kitchens and cladding. Weather conditions and UV light won’t affect the surfaces. Engineered quartz is best for using indoors. The resins used in engineered stone, after exposed to UV rays for longer periods of time, will turn yellow.